Molecular Orientation

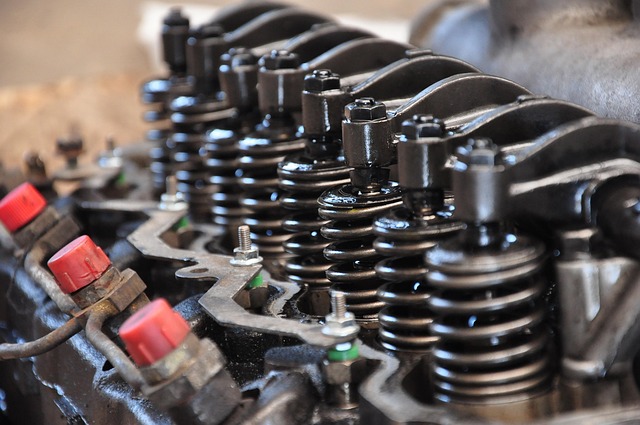

Molecular orientation refers to the alignment of macromolecules within a material, which significantly influences its mechanical and physical properties. This phenomenon occurs during various processing techniques, such as extrusion, injection molding, and calendering. The alignment is particularly pronounced near the interface between the plastic and metal components of molds or dies, where the flow dynamics and cooling rates play critical roles.

The Mechanisms of Molecular Orientation

During processing, the flow of the material causes the macromolecules to stretch and align in the direction of the flow. This alignment is more significant in the outer layers or skins of the material, where the molecules are in direct contact with the tooling and experience rapid cooling. In contrast, the core of the processed material tends to cool more gently, resulting in less molecular stretching and allowing for stress relaxation. This differential cooling and stretching lead to variations in properties across the material.

Impact on Material Properties

The orientation of molecules affects various properties of the material, including tensile strength, elasticity, and thermal stability. For instance, materials with a high degree of molecular orientation in the flow direction exhibit enhanced tensile strength and stiffness. Conversely, properties in the transverse direction may exhibit reversed characteristics, leading to a complex interplay of mechanical behavior.

Factors Influencing Molecular Orientation

Several factors influence the degree of molecular orientation achieved during processing:

- Processing Conditions: The temperature, pressure, and speed of the processing equipment can significantly affect molecular alignment. Higher processing temperatures typically allow for greater mobility of the macromolecules, facilitating better orientation.

- Molecular Structure: The inherent structure of the macromolecules plays a crucial role. Longer molecular backbones tend to exhibit more pronounced orientation effects. Materials designed with stick-, linear-, or planar molecular shapes are particularly effective in achieving high levels of orientation.

- Cooling Rates: Rapid cooling can lock in the orientation achieved during processing, while slower cooling may allow for relaxation of the molecular structure, reducing the overall orientation.

- Material Composition: The presence of additives or fillers can also influence molecular orientation. Certain additives may enhance the flow characteristics of the material, promoting better alignment during processing.

Applications of Molecular Orientation

Molecular orientation is a critical consideration in various applications, particularly in the production of films and fibers. For example, oriented films are commonly used in packaging due to their enhanced strength and barrier properties. Similarly, oriented fibers are utilized in textiles and composite materials, where strength and durability are paramount.

Conclusion

In summary, molecular orientation is a fundamental aspect of material science that significantly impacts the properties and performance of processed materials. Understanding the mechanisms and factors influencing molecular alignment can lead to the development of materials with tailored properties for specific applications. As industries continue to innovate, the role of molecular orientation will remain a key area of focus in the quest for advanced materials.

Pseudorandomness

Pseudorandomness

Health

Health  Fitness

Fitness  Lifestyle

Lifestyle  Tech

Tech  Travel

Travel  Food

Food  Education

Education  Parenting

Parenting  Career & Work

Career & Work  Hobbies

Hobbies  Wellness

Wellness  Beauty

Beauty  Cars

Cars  Art

Art  Science

Science  Culture

Culture  Books

Books  Music

Music  Movies

Movies  Gaming

Gaming  Sports

Sports  Nature

Nature  Home & Garden

Home & Garden  Business & Finance

Business & Finance  Relationships

Relationships  Pets

Pets  Shopping

Shopping  Mindset & Inspiration

Mindset & Inspiration  Environment

Environment  Gadgets

Gadgets  Politics

Politics