Traction Motor

Traction Motor

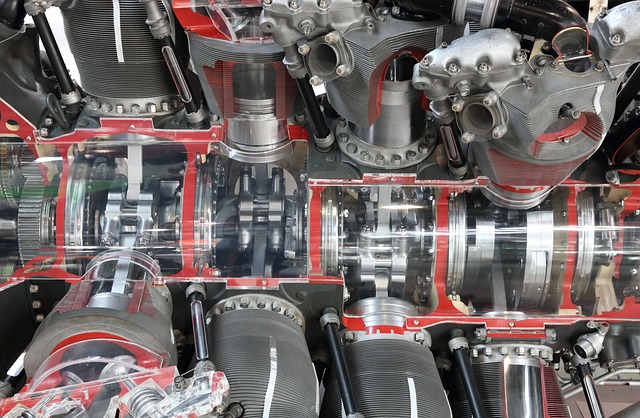

Traction motors play a crucial role in the operation of electrically powered railway vehicles and various other electric vehicles. These motors are designed to convert electrical energy into mechanical energy, facilitating movement and propulsion. The significance of traction motors extends beyond trains; they are also utilized in electric milk floats, trolleybuses, elevators, roller coasters, and conveyor systems, among others.

Types of Traction Motors

There are primarily two types of traction motors: direct-current (DC) motors and alternating-current (AC) motors. Each type has its unique characteristics and applications.

Direct-Current Motors

DC traction motors, particularly those with series field windings, represent the oldest form of traction motors. These motors are characterized by their speed-torque characteristics, which are particularly advantageous for vehicle propulsion. They provide high torque at lower speeds, which is essential for the acceleration of vehicles. As the speed increases, the torque produced by the motor declines, allowing for efficient operation across different speed ranges.

Alternating-Current Motors

AC traction motors have gained popularity due to their efficiency and performance. They are often used in modern electric railways and are supplied with current at lower frequencies than the standard commercial supply used for general lighting and power. This adaptation allows for better operating conditions and enhances the overall efficiency of the traction system.

Operating Principles

The operation of traction motors is based on electromagnetic principles. In a DC motor, both the armature and field current reverse simultaneously, which results in behavior similar to that of a motor energized with direct current. This characteristic is particularly beneficial for applications requiring consistent torque and speed control.

In AC motors, the alternating nature of the current allows for smoother operation and better control over speed and torque. The design of these motors often includes advanced features such as variable frequency drives, which enable precise control over the motor's performance.

Applications of Traction Motors

Traction motors are integral to various applications, particularly in the transportation sector. Their use in electric multiple units (EMUs) and diesel-electric locomotives highlights their versatility. In addition to rail transport, traction motors are employed in electric hybrid vehicles and battery electric vehicles, contributing to the growing trend of electrification in transportation.

Furthermore, traction motors are essential in industrial applications, such as conveyor systems and elevators, where reliable and efficient movement is required. Their ability to provide high torque at low speeds makes them suitable for heavy-duty applications.

Future Trends

As the demand for sustainable and efficient transportation solutions increases, the role of traction motors is expected to expand. Innovations in motor design, materials, and control systems are likely to enhance the performance and efficiency of traction motors. The integration of smart technologies and automation in traction systems will further optimize their operation, leading to improved energy efficiency and reduced operational costs.

In conclusion, traction motors are a vital component in the realm of electric propulsion systems. Their diverse applications and continuous evolution underscore their importance in modern transportation and industrial systems. Understanding the principles and applications of traction motors is essential for professionals in the field, as it lays the foundation for advancements in electric vehicle technology and sustainable transport solutions.

Regulatory Charges by DHL

Regulatory Charges by DHL

Health

Health  Fitness

Fitness  Lifestyle

Lifestyle  Tech

Tech  Travel

Travel  Food

Food  Education

Education  Parenting

Parenting  Career & Work

Career & Work  Hobbies

Hobbies  Wellness

Wellness  Beauty

Beauty  Cars

Cars  Art

Art  Science

Science  Culture

Culture  Books

Books  Music

Music  Movies

Movies  Gaming

Gaming  Sports

Sports  Nature

Nature  Home & Garden

Home & Garden  Business & Finance

Business & Finance  Relationships

Relationships  Pets

Pets  Shopping

Shopping  Mindset & Inspiration

Mindset & Inspiration  Environment

Environment  Gadgets

Gadgets  Politics

Politics