What is DLC Coating?

Diamond-like carbon (DLC) coating is a remarkable material that brings some of the best properties of diamond to a variety of surfaces. Imagine a superhero suit for your tools, car parts, or even your favorite kitchen knives. Yes, it’s like giving them a shiny, protective layer that could probably fend off a light attack from a rogue kitchen utensil! 🥄

How Does DLC Work?

To understand DLC, let's dive a little deeper into the science pool without needing a snorkel. DLC is an amorphous carbon material, meaning it doesn’t have a definite crystalline structure like traditional diamonds. Instead, it can exist in several forms, which is why we say it’s a bit of a shape-shifter. There are seven different types of DLC, each with varying properties, but they all share the common goal of enhancing durability.

Why Use DLC Coating?

Now, you might be wondering, why go for DLC coating? Well, it offers a plethora of benefits:

- Scratch Resistance: DLC coatings are tough cookies, resisting scratches and wear like a champ.

- Low Friction: Sliding surfaces coated with DLC can glide smoothly, which is great for reducing wear and tear.

- Corrosion Resistance: It’s like a raincoat for your metal parts, protecting them from rust and other nasty elements.

- Enhanced Aesthetics: Let’s face it—who doesn’t want their tools or gadgets to look sleek and shiny?

In short, DLC coatings can make ordinary materials feel like they just graduated from a prestigious university of toughness.

Applications of DLC Coating

DLC coatings are versatile and can be found in various industries, from automotive to medical devices. Here are a few examples:

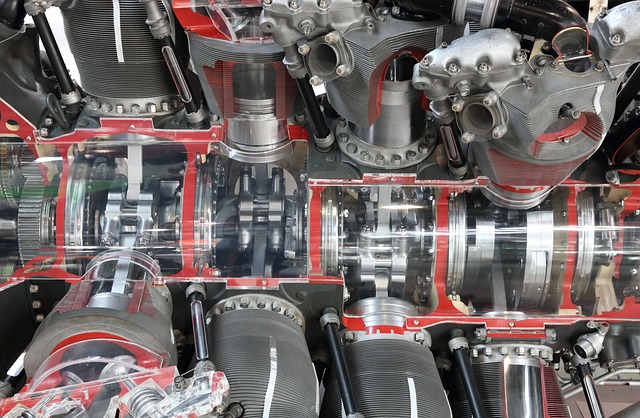

- Automotive Parts: Engine components, gears, and even brake calipers can benefit from the durability of DLC.

- Cutting Tools: Think of those kitchen knives that slice through tomatoes like they’re made of butter—DLC helps keep them sharp and resistant to damage.

- Electronics: Smartphone screens and other gadgets often get a DLC coating to improve scratch resistance.

- Medical Devices: Surgical instruments can be coated with DLC to enhance their longevity and performance.

How is DLC Coating Applied?

The application of DLC coating is a bit of a science experiment. It involves a process called chemical vapor deposition (CVD), where carbon-containing gases are used to create a thin layer of DLC on the surface of the material. It’s like giving your tools a fancy spa treatment, but instead of cucumbers on their eyes, they get a luxurious layer of diamond-like goodness.

Final Thoughts

In conclusion, DLC coating is a fascinating and practical technology that combines the best aspects of diamond with flexibility and versatility. Whether you’re looking to enhance the durability of your tools or just want to impress your friends with some cool science facts, DLC has got you covered. Just remember, while it may not make your coffee, it will definitely keep your kitchen gadgets in top shape! ☕

Dean Devlin

Dean Devlin

Health

Health  Fitness

Fitness  Lifestyle

Lifestyle  Tech

Tech  Travel

Travel  Food

Food  Education

Education  Parenting

Parenting  Career & Work

Career & Work  Hobbies

Hobbies  Wellness

Wellness  Beauty

Beauty  Cars

Cars  Art

Art  Science

Science  Culture

Culture  Books

Books  Music

Music  Movies

Movies  Gaming

Gaming  Sports

Sports  Nature

Nature  Home & Garden

Home & Garden  Business & Finance

Business & Finance  Relationships

Relationships  Pets

Pets  Shopping

Shopping  Mindset & Inspiration

Mindset & Inspiration  Environment

Environment  Gadgets

Gadgets  Politics

Politics