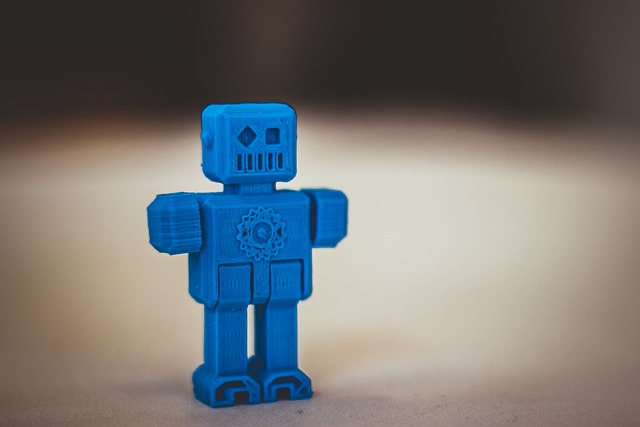

3D Printing: The Future of Manufacturing

3D printing, also known as additive manufacturing, has come a long way since its inception. This innovative technology has revolutionized the way we think about production, allowing for the creation of complex shapes and designs that were once deemed impossible. Whether you're a hobbyist or a professional, understanding the ins and outs of 3D printing can open up a world of possibilities. Let’s dive into what makes this technology so compelling.

What is 3D Printing?

At its core, 3D printing is a process that creates three-dimensional objects layer by layer. Unlike traditional subtractive manufacturing, which involves cutting away material to create an object, 3D printing adds material to build up the final product. This method allows for intricate designs, such as internal truss structures that reduce weight while minimizing waste. Pretty cool, right? 😎

Applications of 3D Printing

The applications of 3D printing are vast and varied. Here are some of the most exciting areas where this technology is making waves:

- Prototyping: Designers and engineers can quickly create prototypes to test ideas, speeding up the development process.

- Medical Devices: Custom prosthetics and implants can be tailored to individual patients, improving comfort and functionality.

- Aerospace: Lightweight components can be produced to enhance fuel efficiency and performance in aircraft.

- Art and Design: Artists are using 3D printing to push the boundaries of creativity, crafting unique sculptures and installations.

Advantages of 3D Printing

So, why should you care about 3D printing? Here are some key advantages:

- Complex Geometries: As mentioned, 3D printing allows for the creation of complex shapes that are impossible to achieve with traditional methods.

- Reduced Material Waste: By adding material only where it’s needed, 3D printing minimizes waste, making it a more sustainable option.

- Customization: Products can be easily tailored to meet specific needs, whether it’s for an individual or a small batch of items.

- Cost-Effectiveness: For low-volume production, 3D printing can be more economical than traditional manufacturing methods.

Challenges Facing 3D Printing

Despite its many benefits, 3D printing is not without challenges. Here are a few hurdles the industry is currently facing:

- Material Limitations: While the range of materials available for 3D printing is expanding, it’s still not as extensive as traditional manufacturing.

- Speed: Printing can be time-consuming, especially for larger objects, which can be a drawback for mass production.

- Regulatory Issues: In industries like healthcare and aerospace, strict regulations can slow down the adoption of new technologies.

The Future of 3D Printing

As technology continues to advance, the future of 3D printing looks bright. Innovations in materials, speed, and scalability are on the horizon, promising to make this technology even more accessible and efficient. Imagine a world where you can print everything from your morning coffee mug to complex machinery parts right at home! ☕

Conclusion

3D printing is more than just a trend; it’s a game-changer in the world of manufacturing. With its ability to create complex designs, reduce waste, and customize products, it’s no wonder that industries are embracing this technology. Whether you’re looking to prototype a new product or create something entirely unique, 3D printing offers endless possibilities. So, are you ready to jump on the 3D printing bandwagon?

Introducing Fish and Chix Derry: A Seafood Dream Come True

Introducing Fish and Chix Derry: A Seafood Dream Come True

Health

Health  Fitness

Fitness  Lifestyle

Lifestyle  Tech

Tech  Travel

Travel  Food

Food  Education

Education  Parenting

Parenting  Career & Work

Career & Work  Hobbies

Hobbies  Wellness

Wellness  Beauty

Beauty  Cars

Cars  Art

Art  Science

Science  Culture

Culture  Books

Books  Music

Music  Movies

Movies  Gaming

Gaming  Sports

Sports  Nature

Nature  Home & Garden

Home & Garden  Business & Finance

Business & Finance  Relationships

Relationships  Pets

Pets  Shopping

Shopping  Mindset & Inspiration

Mindset & Inspiration  Environment

Environment  Gadgets

Gadgets  Politics

Politics